2024 February Stewardship Advocate

This month’s Stewardship Advocate focuses on saturated buffers, an edge of field practice that cleanses the water draining from tiled fields. This article describes the design of this practice, the effect on water quality and cost-share options that can defray most or all of the installation costs. While saturated buffers are less than a 10-12 year old practice, they are gaining in popularity in Iowa. The potential growth is notable in Iowa; there are estimates that Iowa has the landscape to host 70,000-100,000 saturated buffers on more than 14,000 miles of streambanks suitable for saturated buffers.

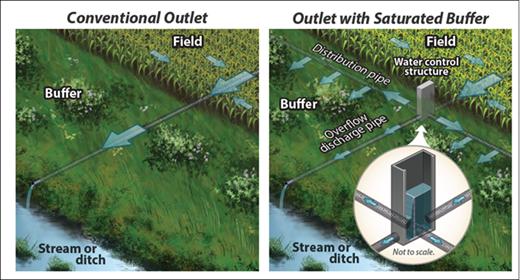

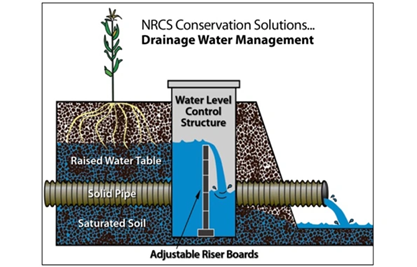

Saturated buffers have underground pipes that divert tile-drained water from cropland through a vegetated buffer. The vegetation removes sediment, nitrates and pesticide run-off, while creating a wildlife habitat. Saturated buffers work the best in fields with tile lines that slope toward a stream or drainage ditch. The water control structure directs a portion of the flow to perforated distribution pipes that run parallel to the stream or drainage ditch. Figure 1 below compares the drainage patterns of a conventional outlet (left) with a saturated buffer outlet. One feature of the water control structure is the ability to control the water table level in the field being drained by adding or removing “riser boards” in the structure. Figure 2 shows a saturated buffer being installed.

Siting saturated buffers

Positioning saturated buffers is not a one-size fits all proposition because certain conditions are required to maximize their effectiveness and longevity, including:

- Loam or clay loam soil in the buffer strip.

- Absence of a sand or gravel layer within the top 4-5 feet of the surface.

- Stable stream or ditch banks adjacent to the parallel distribution pipe.

- At least a 30-foot wide buffer adjacent to the stream or ditch.

- Soil in the buffer strip should contain at least 1.2% organic matter to a depth of 2-3 feet.

- Buffers should have a high-water table.

- Buffers should be lower in elevation than the field being drained.

Benefits of saturated buffers:

- Decrease nitrate concentration in water entering streams by an average of 42%.

- No impact on crop yields when positioned properly.

- Slows down drainage flow entering stream compared to conventional tile discharge.

- Very little management or maintenance is needed once the saturated buffer is installed.

- Relatively low installation cost, especially with cost-share programs.

- Ability to hold or remove drainage water by using riser boards (Figure 3).

Cost-share programs for saturated buffers

There are numerous cost-share programs for water quality practices in Iowa that can reduce or eliminate the cost of installing saturated buffers. They include:

- Iowa Department of Agriculture and Land Stewardship Water Quality Initiative program (IDALS)

- Natural Resources Conservation Services programs (Iowa NRCS)

- Environmental Quality Incentives Program

- Conservation Reserve Program

- Regional Conservation Partnership Program

- Public-private programs (e.g., Iowa Pork Batch and Build)

Batch and Build

- Batch and build is a new, innovative water quality program that bring together farmers, landowners, cooperatives and realtors, farm organizations, local governments and the Iowa Department of Agriculture and Land Stewardship (IDALS) to get as many water quality practices on the ground as quickly as possible. The batch-and-build approach allows cost-share and private funds to be aggregated and to consolidate projects in a small geographic area. This consolidation approach allows contractors to utilize their personnel and equipment more effectively and locally when installing multiple saturated buffers and bioreactors, thereby reducing total effort and cost.

LATEST INFORMATION

AgriMarketing.com – USDA Reports Technology–Not Increased Inputs–Is Driving Ag Productivity Growth

Agronomists Worry Moisture Deficits Will Contribute To Herbicide Carryover

Sulfur Fertilizer Recommendations

Water Quality and Conservation among Secretary Naig’s Key Priorities

Tall Order for Short Corn: The Latest On Short-Stature Hybrids

Complete These 8 Steps To Transition to Vertical Farming

EPA Issues Existing Stocks Order For Dicamba Products

Iowa Leopold Conservation Award Seeks Nominees| Sand County Foundation

FARMER TO FARMER: STU SWANSON

Stu Swanson and his family farm near Galt, Iowa. He began farming with his dad and grandfather in 1992 after graduating from Iowa State University. The third generation Swanson farm is operated by Stu, his daughter Lilian, a fulltime employee and seasonal part-time help. The Swansons have a 50:50 corn soybean rotation and diversify their operation by finishing hogs and growing seed for a nearby seed production plant.

Stu has a strong commitment to his family and his farm. As a third-generation farmer in Wright County, his overall goal is to continue to build an operation that can be passed to the fourth and fifth generations. Stu says, “This can only happen if I am a steward of the land and assets. I take pride in making improvements to the land on and water coming off our farms. But this succession plan will not be just a simple transaction of land but also about passing a passion for agriculture and ensuring the land is in better shape than when I received it.” Evidence of this commitment is the installation of eight miles of buffer strips along drainage ditches, well positioned grassed waterways and CRP wetlands.”

The Swansons normally plant a suite of hybrids from 100-110 RM at a population of 35,000 seed per acre. Swine manure is utilized as the base of his corn fertility program with commercial fertilizer applied on the balance of the acres based on distance from manure facilities. On acres without manure, they split-apply nitrogen with 75% in the fall as stabilized anhydrous ammonia and the other 25% as liquid nitrogen in the spring.

In 2023, planting began on April 11 and was done on May 2. The fall corn harvest began on September 13 and was completed on October 17. He delivers his corn to a local feed mill where it is processed and returned to his farms as feed. 2023 was the third consecutive year of D2-D3 drought in southeast Wright County. Stu noted, “Rainfall was highly variable with a range of 9-16 inches. Typical rainfall is 30-32 inches for our farms so we got a third to a half of normal. Yields were also highly variable this year based on rainfall with the whole farm yield down 10-15%.”

Stu is looking ahead to the 2024 season and is taking into account what he learned in 2023 to chart his path this coming season. “In 2024, I will be prepared for early planting if soil conditions are fit. I am considering planting soybeans ahead of corn if the conditions are right. I’ll be more patient in regard to fungicide application and utilize scouting apps for tar spot. I also will be changing chemical groups within my applications to better manage weed resistance.”

When asked about what he wants others to know about his farm, Stu explains, “I am looking for ways to improve my operation every year through trials of new products and utilizing new technology. The goal of these trials is to improve my profitability and do my part to improve farm sustainability. I cannot afford to be complacent because technology will pass me by. I seek input from several different sources when it comes to new technology, whether that be seed choices or equipment. I have also been greatly influenced by my dad in this area as he truly enjoyed working on upgrades to these systems during his career. In the end, I make the final decision based on an ROI evaluation to see if the technology is beneficial to my operation.”

While his farming operation is more than a full-time job, Stu finds time to give back to Iowa corn farmers. “I have been a member of Iowa Corn every year that I have farmed and believe farmers and agriculture can be stronger by working together.” Stu has served on several Iowa Corn committees and currently serves as Iowa Corn Growers Association’s first vice president. He also participates on a national and international level. He relishes the chance to advocate for Iowa Corn. “One of my most impactful moments with Iowa Corn was meeting with Mexican corn buyers in their country to learn about what they need from Iowa corn growers to be successful. And then, I had the honor of hosting them on my farm to show them how I raise corn and explaining how we can be a reliable supplier for them. It was important for each of us to understand our business needs and capability, that led to a meaningful and lasting relationship and that’s what it’s all about.”

UPCOMING EVENTS:

February 28: Soil Conservation and Water Management – the Keys to Improving Climate Resilience; Dr. Rick Cruse; Webinar

March 6: Southwest Iowa Winter Soil Health Conference; Atlantic; register at Southwest Iowa Soil Health Conference

March 7: Virtual Field Day – Exploring Sustainable Intensification on Iowa’s Landscape through Relay Intercropping; Webinar

March 8 (11:00 – 1:00): Farming for the Future Friday; WHO Big Show with the Iowa Beef Industry Council

March 21: Virtual Field Day – A New Direction in Cover Crops: Developing Perennial Ground Cover for Corn Systems in the Midwest; Webinar