Research for Innovative New Corn Uses

Checkoff funds invested by the Iowa Corn Promotion Board (ICPB) are finding and developing new ways to use corn, such as in bioplastics, renewable fuels and other products.

Research Investments & the Potential Impact

Our strategy is to “derisk” a technology enough to attract companies and partners that can bring the technology to market. Because major companies are unable to derisk every single idea, they are embracing open innovation as a way to fill their research and development pipelines.

Develop technology to increase corn utilization and develop new traits.

License or sell patented inventions to companies for commercialization.

Invest in start-up companies related to corn utilization and traits.

Fund basic research to understand the function of corn’s genetic code.

ICPB Investments & Projects

Plastic companies want renewable materials at a cost that’s competitive with petroleum. Therefore, converting corn to bioplastics has been a major research focus for ICPB. One such avenue is producing monoethylene glycol (MEG) from corn sugar. To grow this market, ICPB sold its patents, technology, and know-how for producing MEG from corn sugar to Technip Energies, a global licensing and engineering company for chemical processes.

The Impact: MEG can be used to manufacture polyester plastic that’s used in bottles and textiles as well as for antifreeze. Over 75 billion pounds of MEG are used in the world every year, with annual market growth equating to nearly 100 million bushels of corn.

ICPB has invested in Låkril’s proprietary technology that converts corn-based lactic acid to acrylic acid. Thanks to technology delivering impressive acrylic acid yields, Låkril has been able to produce plant-based acrylic acid alternatives at costs on par with those using petroleum ingredients.

The Impact: More than 15 billion pounds of acrylic acid are produced globally each year from petroleum for use in products like diapers, paints and coatings and adhesives. If switched to a plant-based alternative, that would equate to about 800 million bushels of annual corn use.

ICPB has invested in ClearFlame Engine Technologies’ research on utilizing corn-based ethanol to fuel diesel engines. The startup company has a patented system that transforms diesel engines in semitrucks, agriculture equipment and stationary power generators to run on 100% denatured ethanol. The ClearFlame system also lowers tailpipe and greenhouse gas emissions and drops the total cost of operation approximately 40 cents per mile, without sacrificing any power, torque or efficiency compared to diesel-powered engines.

The Impact: There are over 4 million semi-trucks on the road today. If 1% of those trucks (about 40,000) adopted ClearFlame technology, that would add 1 billion gallons of new ethanol demand, utilizing nearly 350 million bushels of corn per year.

Cargill and HELM are working on a joint venture to commercialize a drop-in chemical that utilizes corn sugar in fabrics, a chemical that could disrupt petroleum’s dominance in the fabrics and materials space. This joint venture known as Qore includes the construction of a plant next to the Cargill wet mill in Eddyville, Iowa, that will replace fossil fuels with corn sugar as the feedstock for 1,4-butanediol (BDO). BDO can be used to make spandex, soles of shoes, grips on power tools, watch bands, artificial leather, golf balls and athletic wear. The plant-based product will save up to 93% of greenhouse gas emissions compared to fossil fuels. ICPB is excited about the potential for corn-based fabrics and is helping these brands and others connect with farmers to better understand the role of sustainability in corn farming.

The Impact: Replacing fossil fuels with corn sugar as the feedstock in these materials could utilize over 9 million bushels of corn every year.

ICPB is also focused on other new chemical projects centered around corn, including turning corn into flip-flop soles, PVC pipes and as a replacement to per- and polyfluoroalkyl substance (PFAS; also called forever chemicals) in plastics.

The Impact: These new corn-based chemicals could add more than 100 million bushels to corn demand each year over the next 10 to 15 years.

ICPB has invested in the development of a patented process to convert sugar directly to propylene glycol (PG), a clear, colorless liquid used to help absorb water and maintain moisture and texture. It’s used in medicines, cosmetics and food.

PG is typically produced from petroleum, but it can also be made from glycerine, a biobased byproduct of biodiesel production. That means corn oil, corn gluten meal and corn gluten feed produced at a wet mill could all be used to produce PG. Iowa Corn is seeking partners interested in commercialization of this PG process.

The Impact: Over 5 billion pounds of PG are used in the world every year, with annual market growth equating to nearly 10 million bushels of corn.

ICPB is co-funding a project to develop a Direct Ethanol Fuel Cell (DEFC) designed to power an electric generator or motor using pure ethanol. DEFCs are unique from other fuel cells in that they use ethanol directly; they do not convert it into hydrogen or other fuels prior to use. In addition to using a cleaner, homegrown fuel, these ethanol-powered fuel cells also eliminate the safety and handling concerns associated with compressed flammable gases like hydrogen.

This project, which is also supported by 13 other corn state checkoffs and the National Corn Growers Association (NCGA), seeks to derisk a patent-pending catalyst and further demonstrate commercial value of converting ethanol into electricity.

The Impact: Telecommunications, disaster assistance, vehicles, the military and individuals use generators and other electric motors extensively. A safer and cleaner ethanol-fueled option could drive significant corn use.

Iowa Corn continues to monitor and investigate opportunities for ethanol to be used to produce sustainable aviation fuel (SAF). Corn sugar can be converted to “biocrud” that is then made into SAF; CO2 from ethanol production can also be converted to SAF either by first converting it to ethanol or methanol. But the ethanol to SAF conversion process is a competitive one, and eligibility for related federal tax incentives depends on the carbon intensity score of the final SAF product.

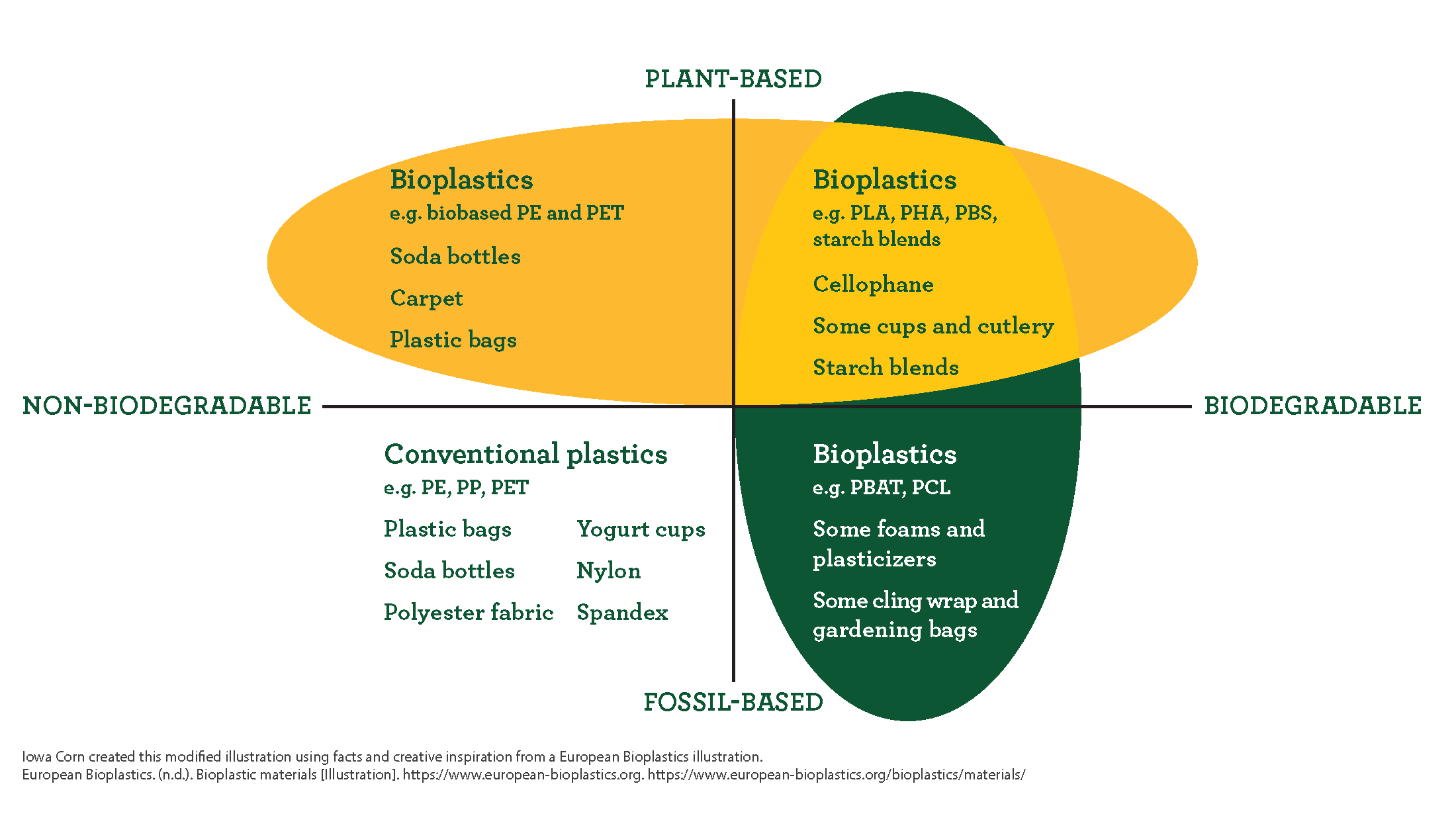

Learn the difference between the many types of plastic you use every day and which ones can be made from corn.

Learn more about our partners working to find new uses for Iowa Corn.